2024-03-29

SY-2394 development background

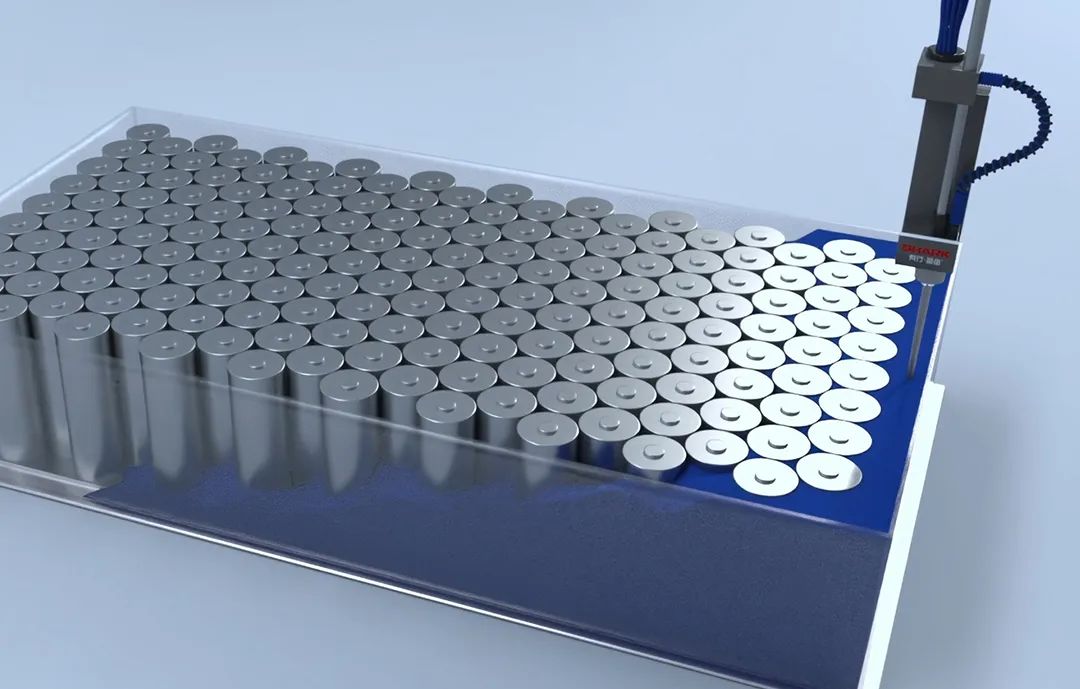

In the rapid development of new energy vehicles, the optimization of battery performance has become the focus of the industry. Among them, lightweight and thermal management are two core issues, which are directly related to the energy efficiency, performance, safety and reliability of the vehicle. With its strong R&D capabilities, Youxingsha has launched a low-density flame-retardant and heat-insulating potting compound - SY-2394, providing a new solution for power battery cells.

SY-2394 product description

Youxingsha SY-2394 is a two-component addition-type silicone low-density flame-retardant and heat-insulating potting glue with a ratio of 1:1 (mass ratio or volume ratio). It can be cured at room temperature or heated. It has good heat resistance, electrical insulation and fire insulation properties; good elasticity, low stress, anti-vibration and impact resistance; and excellent aging resistance. This product is solvent-free and friendly to the human body and the environment. It does not release small molecules during the curing process, has no corrosion to the substrate, and has a wide range of applications.

SY-2394 main application areas

Used in lightweighting of new energy vehicles or power battery cells and modules, buffering, shock absorption, and thermal insulation protection;

Applied to the protection of electronic components.

SY-2394 Some technical parameters

The above parameters are tested at 25℃

SY-2394 Recommended Curing Conditions

AB component volume ratio or mass ratio is 1:1, 24hrs @25±2℃, 65%±10%RH, surface drying time 65min±5 @25℃.

SY-2394 characteristics after curing

SY-2394 focuses on performance (1)

Fire insulation and flame retardant properties:

At present, battery safety has become one of the factors that consumers pay most attention to when purchasing pure electric vehicles.

Improper battery thermal management can easily lead to safety accidents. Thermal runaway caused by improper thermal management is the main reason for power battery fires. Therefore, in addition to insulation and voltage resistance, when selecting battery materials, it is also necessary to focus on fire protection, heat insulation and flame retardant properties.

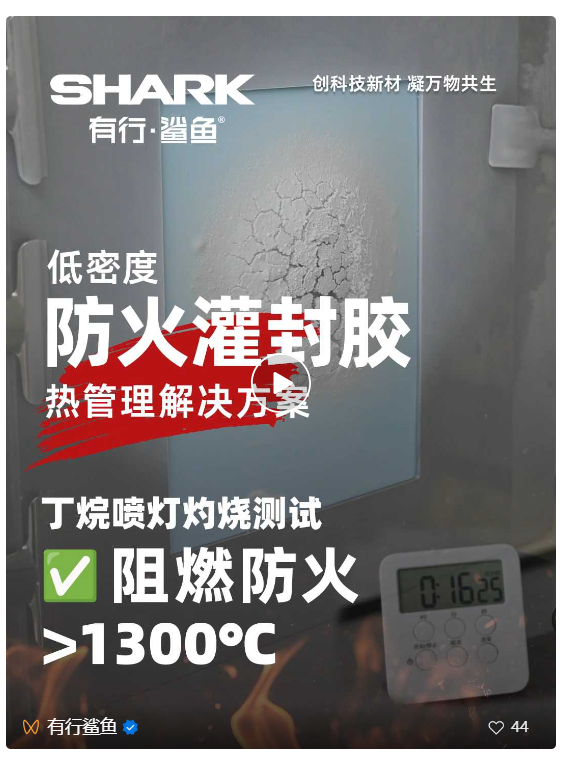

According to the "Three Mandatory Standards" organized by the Ministry of Industry and Information Technology, a 5-minute escape time is required in case of battery thermal runaway. Youxingsha's low-density flame-retardant heat-insulating potting compound SY-2394 has excellent heat-insulating and flame-retardant properties. It has UL-94 V-0 level flame-retardant properties and can remain inert for more than 15 minutes at a high temperature of 1300°C. The fire resistance of burn-through provides a strong safety barrier for the battery system, effectively preventing thermal runaway accidents and ensuring the safety of passengers.

SY-2394 Flame retardant and thermal insulation performance test

Experimental conclusion: SY-2394 colloid is burned at a high temperature of 1300°C for 15 minutes, and the flame retardant and heat insulation does not burn through.

As a low-density flame-retardant and heat-insulating potting compound specially customized for the new energy vehicle field, SY-2394 meets customers' stringent requirements for high performance. It surpasses common products on the market in multiple key indicators: while maintaining excellent fire resistance and flame retardant properties, it achieves a density as low as 0.7-0.8g/cm³, compared to 0.9-1.0g/cm³ on the market. A mainstream product, this breakthrough lightweight design has brought significant weight reduction to the battery modules of new energy vehicles. For related experiments, please pay attention to the next article for details.